Low Volume Extrusion Services

Combine with CNC and Other Methods

Global Delivery

in 2-3 Weeks

Aluminum Extrusion Services

If you’re searching for aluminum extrusion or custom aluminum extrusion solutions—whether it’s a one-off aluminum extrusion prototype, low-volume aluminum profiles, or tailored aluminum parts—most dedicated extrusion companies will turn you away due to high minimum order quantities (MOQs). At Zigitech, we specialize in solving this pain point: our in-house extrusion workshop and integrated manufacturing capabilities are built for aluminum extrusion, with a laser focus on custom aluminum extrusion and low-volume needs. We don’t just produce aluminum parts—we tailor every step (from alloy selection to finishing) to your design, while ensuring strict quality control before global delivery (2-3 weeks, half the industry’s standard time).

Custom Aluminum Extrusion: Bring Your Design to Life

Alloy customization

Our standard, high-performance alloys are 6061 and 6063 (both rich in magnesium and silicon, offering exceptional corrosion resistance). 6061 is ideal for structural aluminum parts (e.g., frames, supports) due to its high strength; 6063 excels at precision shapes (e.g., trim, decorative profiles) with smooth surface quality. We also evaluate and accommodate your specified aluminum alloys—just share your requirements, and we’ll confirm feasibility during quoting.

Integrated post-processing

No need to work with multiple suppliers. We combine aluminum extrusion with CNC milling, CNC turning, or bending to transform extruded profiles into finished, ready-to-use custom aluminum parts—saving you time and streamlining production..

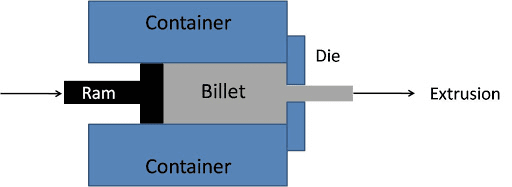

What is Aluminum Extrusion?

Aluminum extrusion is the process of shaping aluminum material by forcing it to flow through a shaped opening in a die. When extruded in this way, the aluminum material comes out of the die as an elongated piece with a continuous cross-sectional profile, and this profile can be highly complex and detailed. For non-specialists, an easy explanation of extrusion is to think about how pasta shapes or Play-Doh are made. In both cases, dough is fed into a chamber, pressure is applied by turning a crank or handle, and strands of the stuff are squeezed out of a small hole. Changing the attachment for this hole affects the cross-section of the strands, giving you the choice between e.g. tagliatelle, penne, or something else.

Of course, aluminum billets aren’t quite as malleable as pasta dough, so the aluminum extrusion process requires a lot of force — typically via huge amounts of hydraulic pressure — and, in some cases, the application of heat.

How Does Aluminum Extrusion Work?

The aluminum extrusion process can be carried out in one of two ways: hot extrusion or cold extrusion. There are reasons to use both methods. Hot extrusion allows for greater volumes of aluminum to be fed into the die, quickly and at lower pressure, while cold extrusion can produce mechanically superior parts with a good surface finish and resistance to oxidization.

To extrude aluminum via the hot extrusion process, aluminum billets must first be cut to an appropriate size. They are then heated in an oven to a temperature between 300 °C and 600 °C, making the metal supple but not liquid.

When the cut aluminum billets are heated, a ram powered by hydraulic pressure forces them into the die, which may have a standard aperture (i.e. a round or square hole) or a custom-made profile. A huge amount of pressure — around 10,000,000 pounds — is required to force the heated aluminum through the die.

The extrusions are then cooled on a cooling table, before being cut into lengths according to the customer’s demands. Heat treatment can also be applied to harden the aluminum.

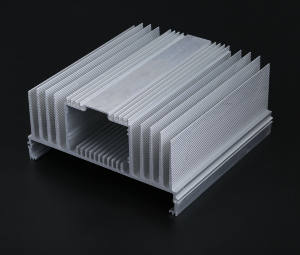

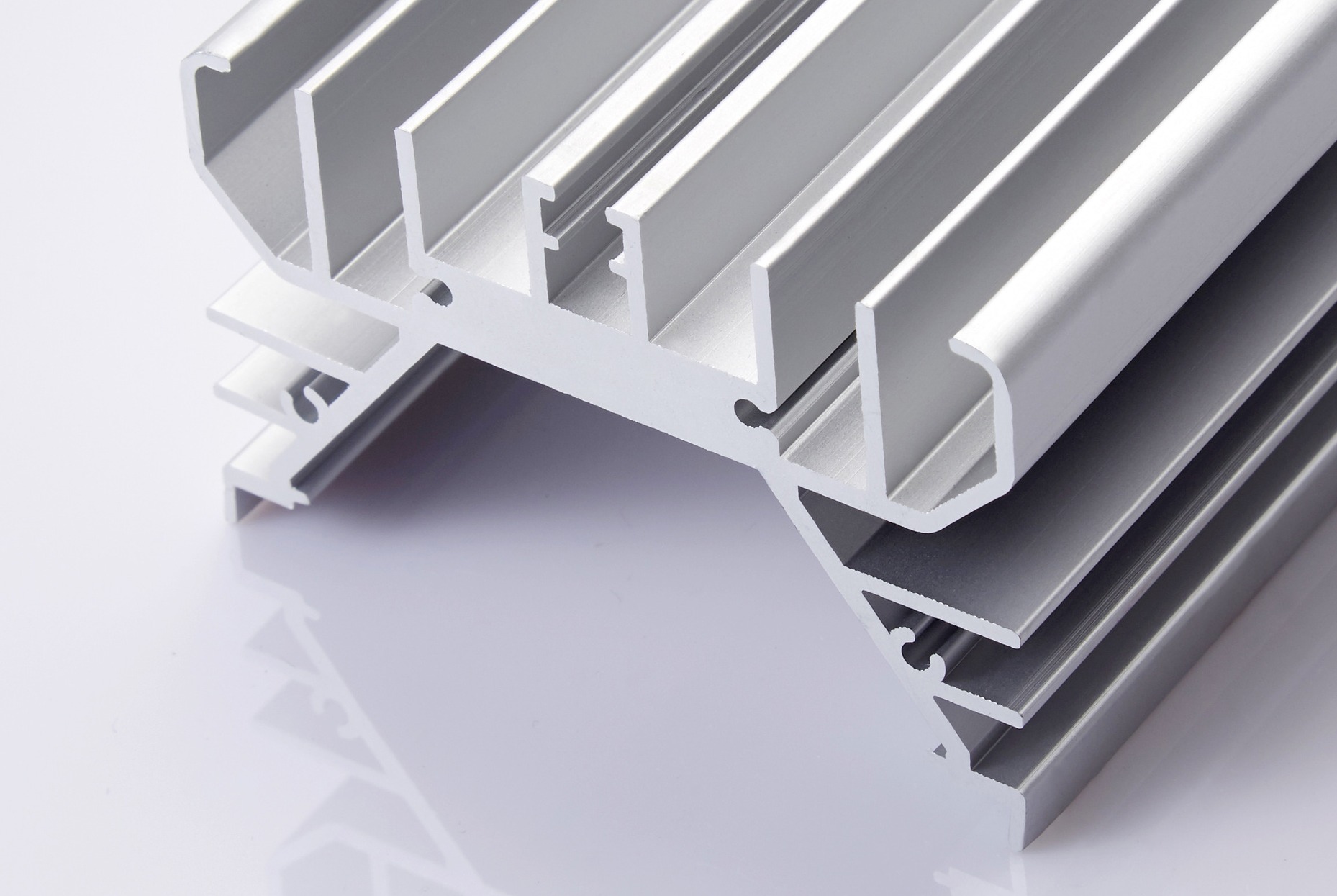

Standard Aluminum Extrusion Profiles

Custom aluminum extrusion profiles can be cut to any 2D cross-sectional shape. However, there are several standard aluminum extrusion profiles suitable for many projects, including extruded aluminum bar and extruded aluminum channel of various forms.

Standard profiles include:

- Circular bar

- Square bar

- Circular tube

- Square tube

- L-shape

- U-shape

- T-shape

- C-shape

- J-shape

- F-shape

Profiles also come in standard sizes and series. These include:

- 2020 aluminum extrusion (20 mm x 20 mm)

- 80/20 aluminum extrusion (T-slot aluminum extrusion)

- 2040 aluminum extrusion (20 mm x 40 mm)

- 3030 aluminum extrusion (30 mm x 30 mm)

Custom Aluminum Extrusion Profiles: Low-Volume, Prototyping & Custom Shapes

Standard aluminum extrusion profiles (such as extruded aluminum channel, extruded aluminum bar, or other mass-produced geometries) are often manufactured in bulk by large-scale extrusion specialists. If your project requires high-volume orders of standard aluminum extrusion profiles, partnering with these mass-production-focused companies may offer the best cost efficiency.

However, for custom aluminum extrusion profiles with nonstandard aluminum extruded shapes — or when you need low-volume aluminum extrusion for prototyping, small batch production, or unique designs — Zigitech is the ideal solution. We specialize in accepting low-volume extrusion orders, so you can test and iterate on custom aluminum extrusion profiles without being limited by high minimum order quantities (MOQs).

Beyond crafting custom aluminum extrusion profiles with precision custom dies, we integrate aluminum extrusion with other advanced manufacturing processes (including CNC machining, bending, and finishing). This end-to-end capability allows us to produce fully customized final parts more quickly and affordably — especially when parts feature a consistent cross-sectional shape (a core advantage of aluminum extrusion).

Example operations:

Creating a custom extrusion, then using a CNC mill to add details, holes, or threads.

Creating a round extrusion, then using a CNC lathe to add taper or other features.

Creating a custom extrusion, then adding text or other engraving with a laser cutter.

Finishing Options for Custom Aluminum Extrusion: Elevate Durability & Aesthetics

Aluminum extrusion is used to mass produce lots of non-cosmetic parts like tubing and frames, where finishing may not be especially important. However, custom aluminum extrusion is also used to produce high-value products which may benefits from the addition of color, text, logos, and other finishing procedures.

Suitable surface finishing procedures for aluminum extrusion include:

- Basic mechanical finishing: Buffing (creates a smooth, reflective shine), bead blasting (delivers a uniform matte texture), or grinding (removes burrs and sharp edges). Ideal for preparing aluminum extrusion parts for further finishing (e.g., anodization) or for non-cosmetic parts that need improved surface quality.

- Anodization: Adds a hard, scratch-resistant, and anti-oxidation coating to custom aluminum extrusion parts. Available in custom colors (clear, black, silver, gold, and more) for a premium cosmetic look—perfect for parts exposed to weather, moisture, or frequent use.

- Painting: Delivers matte, gloss, or textured finishes in any Pantone color. A cost-effective way to match aluminum extrusion parts to your brand identity or design scheme.

- Powder coating: A durable alternative to painting. Creates a thick, chemical-resistant finish with consistent tone—ideal for industrial custom aluminum extrusion parts or outdoor applications (e.g., patio furniture frames)..

- Silk-screen printing: The simplest way to add custom text, logos, or graphics to aluminum extrusion profiles. More affordable than machine-based finishing and great for branding components (e.g., product labels, company logos).

- Laser engraving: Creates permanent, high-precision details (e.g., part serial numbers, safety labels, QR codes) on custom aluminum extrusion parts. The engraving won’t rub off over time—critical for traceability or regulatory compliance.

Aluminum Extrusion FAQ

Why choose Zigitech for aluminum extrusion or custom aluminum extrusion?

We’re one of the few companies specializing in low-volume aluminum extrusion and custom aluminum extrusion. Most extrusion providers only handle high-volume orders, but we serve startups, small businesses, and project teams with 1-piece prototypes up to hundreds of units. We also offer end-to-end service (extrusion + post-processing + finishing) and deliver 2x faster than the industry average.

Can you create custom aluminum extrusion profiles with complex 2D cross-sections?

Absolutely. We regularly produce custom aluminum extrusion profiles with intricate details—from thin walls and small slots to unique geometric shapes. Just share your CAD file or design sketch, and we’ll assess feasibility, recommend materials (e.g., 6061 vs. 6063), and provide a clear quote.

What aluminum alloys do you use for custom aluminum extrusion, and can I request a specific one?

Our standard alloys are 6061 (high strength, corrosion-resistant) and 6063 (precision, smooth surface). We can also source and use other aluminum alloys (e.g., 6082 for higher load-bearing parts, 5052 for superior corrosion resistance) based on your needs. We’ll check alloy availability and compatibility with extrusion before confirming your order.

How long does a custom aluminum extrusion project take?

Most custom aluminum extrusion projects (mold manufacturing + extrusion + basic finishing) are ready for global delivery in 2-3 weeks—far faster than the 30+ days other companies require. For urgent projects, we can prioritize production (just let our team know your timeline).

Who manufactures your aluminum extrusion parts, and how do you ensure quality?

All aluminum extrusion processes—from base aluminum extrusion production to custom aluminum extrusion post-processing—are fully completed in Zigitech’s own factory. We do not rely on external partners: our in-house workshop handles every key step, including aluminum billet preparation, die design & manufacturing, extrusion molding (forcing aluminum through custom dies to form profiles), CNC milling/turning/bending, and all surface finishing (anodization, powder coating, etc.).