Automotive Prototyping & Parts Manufacturing

Global delivery as fast as 10 days

Rapid Manufacturing on Demand

Within the automotive industry, the malfunction or failure of a component can lead to

catastrophic consequences. As such, it essential to fully test and evaluate any new

part or product to determine whether it performs as intended before it is available

in the market. For these operations, prototypes are ideal.

At Zigitech, we have

extensive experience prototyping and manufacturing automotive parts, including for

leading automotive companies such as BMW, Bentley Motors, Lamborghini, and Land

Rover. We utilize rapid prototyping techniques to produce high-performance physical

prototypes designed and built to pass some of the most rigorous verification and

testing procedures available.

Advantages of Rapid Prototyping

In the automotive industry, there is constant pressure to

achieve higher performance standards, including those regarding fuel efficiency,

aerodynamics, connectivity, and security. By employing rapid prototyping

techniques, manufacturers experience the following advantages:

- Shorter production times and lower production

costs. One of the main benefits of rapid prototyping is how fast it

is at bringing a product from initial concept to reality. Multiple product

designs can be designed, tested, and evaluated in a shorter time period.

Once a design is finalized, it can then proceed to production without the

risk of needing costly modifications in the future.

- Easier product innovation. Rapid prototyping

enables industry professionals to create functional models of a new part

design quickly. Compared to conventional manufacturing methods, which carry

more extensive design constraints, it also allows for greater customization

of products to meet unique specifications.

- Greater supply chain transformation. Rapid

prototyping changes how parts enter the supply chain. By using it to meet

fluctuating market demand, industry professionals can reduce material

utilization and waste generation, lower inventory costs, and support low to

medium production runs.

- Safer, cleaner, and lighter part designs.

Rapid prototyping allows manufacturers to design and develop safer,

cleaner, and lighter parts. As the process comes with shorter

design-to-delivery times than alternative methods, they can compare more

designs before deciding on which is most effective and efficient.

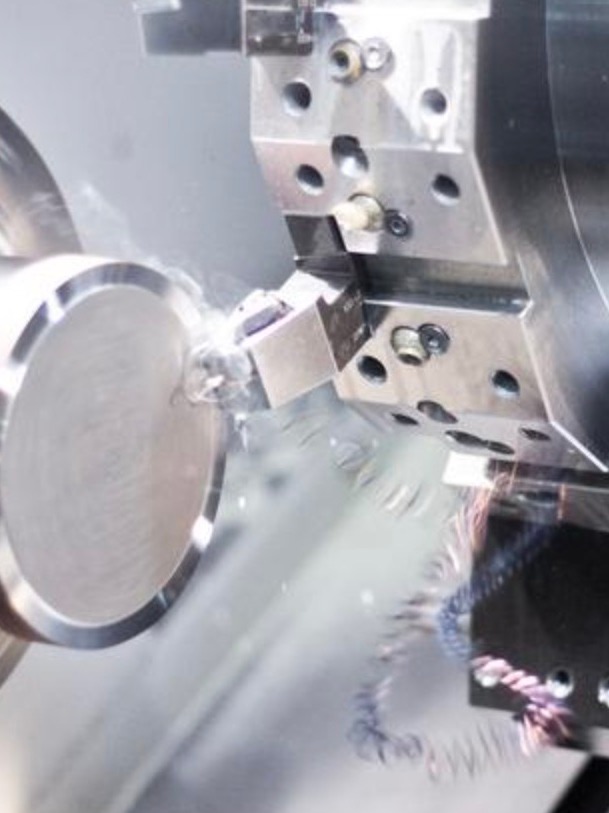

Rapid Prototyping Techniques Employed by Zigitech

At Zigitech, we offer the following rapid

prototyping capabilities for customers in the automotive

industry:

- For engine parts: aluminum

machining

- For interior lighting, exterior

lights, and headlights: acrylic machining

- For quick runs: injection molding

and rapid tooling

- For short-term trial productions:

reaction injection molding (RIM)

Precision Auto Parts Produced Through Rapid Prototyping

We are capable of prototyping interior, exterior, and functional

parts at our facilities.

We produce prototypes for many interior vehicle parts,

such as the steering wheel, dashboard, or console. By utilizing rapid

prototyping, interior parts can be tested for various aspects. For example,

steering wheels can be evaluated for their grip, dashboards can be verified for

color, and consoles can be assessed for the amount of wear they show after use.

The results gathered from these tests can provide insight into whether a design

needs alteration.

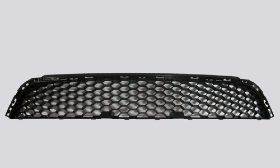

The exterior parts we prototype include bumpers,

headlights/tail lights, and door handles. Exterior part prototypes are generally

tested for safety, such as how the bumper holds up in a simulated crash, how the

lights perform in low light or rain, or how the door handles function with

repeated use. Safety testing, such as failure mode and effect analysis (FMEA),

can also be performed on exterior parts to evaluate the risk of failure in both

everyday use and extreme conditions.

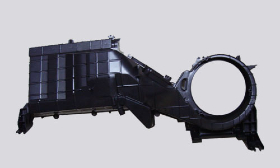

The functional parts that we can prototype include air

components, engine covers, and air filter housings. Functional part prototypes

are primarily tested to ascertain how well they perform within the vehicle. For

example, the air components, engine covers, and air filter housings can be

prototyped and tested to see how they function in the high-temperature

environment generated by the engine.

Automotive

Prototyping At Zigitech

At Zigitech, we provide automotive

industry customers with rapid prototyping and manufacturing

solutions. Our expert team has the knowledge and skills to

help bring new product concepts to life. For more

information on our prototyping capabilities and how we serve

the automotive industry, contact us or request a quote today.