Zigitech rapid prototype manufacturing services are applicable throughout the industrial equipment industry. Visualizing how a given prototype is likely to perform in the real application environment is a critical phase during any product design process. We subject our prototypes to stress and strain tests, and this ensures that we can eliminate any factor that might introduce failure in the systems we develop. Other tests we conduct include chemical resistance, mechanical properties, thermal properties, electrical properties, standards testing, and durability.

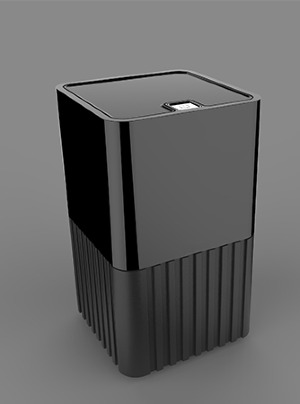

Consumer electronics are intense and notoriously competitive. You need the support to be able to bring the highest quality parts to market in the fastest lead times.

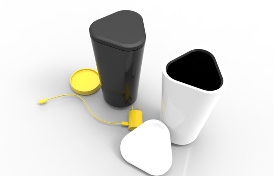

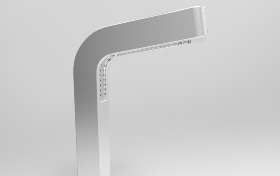

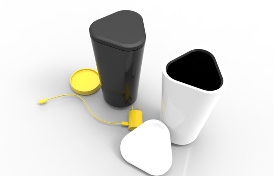

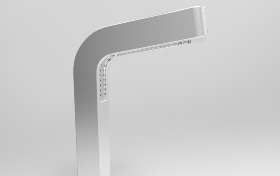

Vacuum casting: great for low volume production quality plastics Rapid injection molding: real production parts from low-cost tooling, reducing risk 3D printing: rapid iterations and low volume parts.

Aesthetic models, trade show models, marketing models, prototypes, functional parts, low volume production.

At Zigitech, we manufacture prototype and low-volume rapid parts for consumer product projects via CNC machining, 3D printing, rapid injection molding, die casting, sheet metal, vacuum casting (urethane casting), and more.