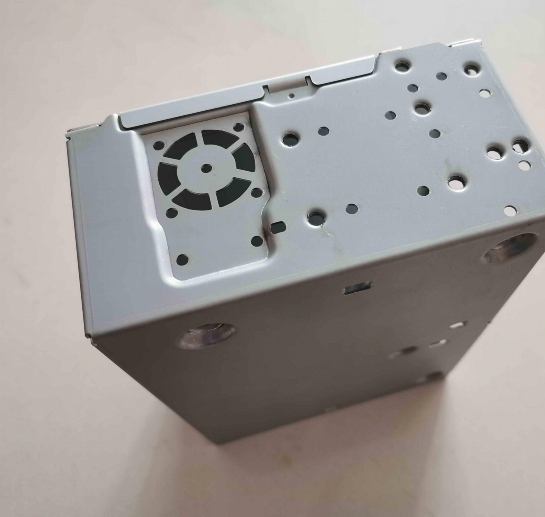

In simpler terms, you use technology to transform a product idea into a physical model.

This early physical model is a prototype. You’ll then refine this until you get the final version right. At that point, you’re ready to use or sell this into a product. So the faster you produce and refine your prototypes, the faster you can start going to market.

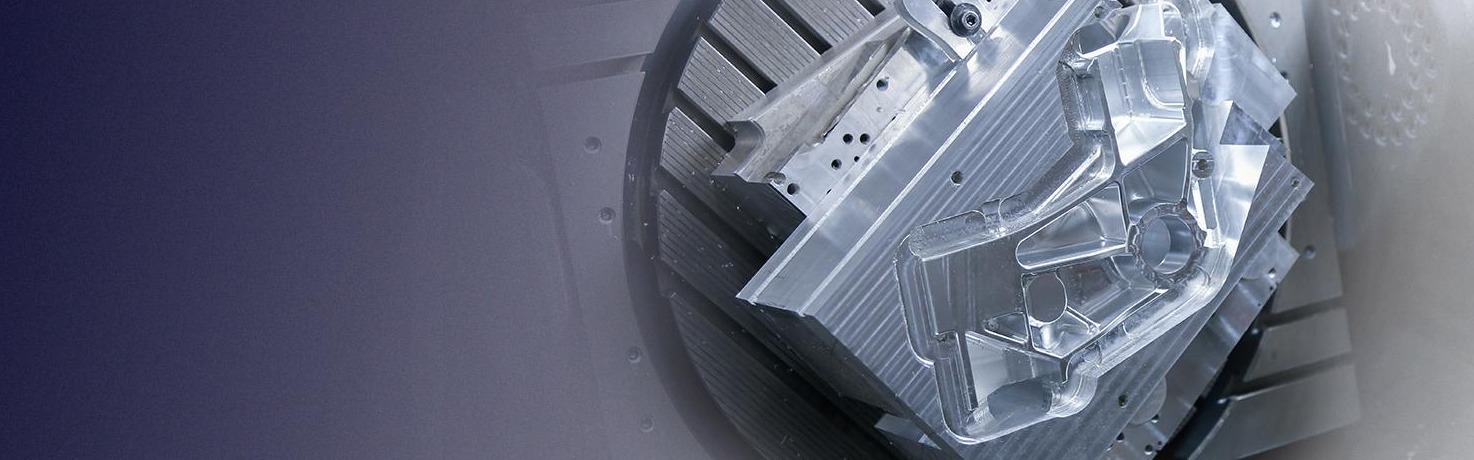

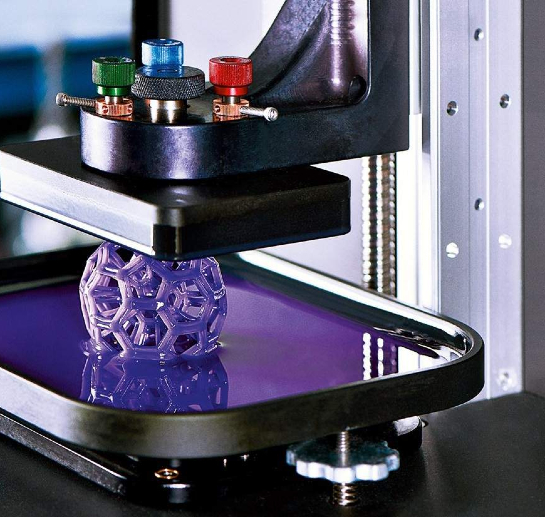

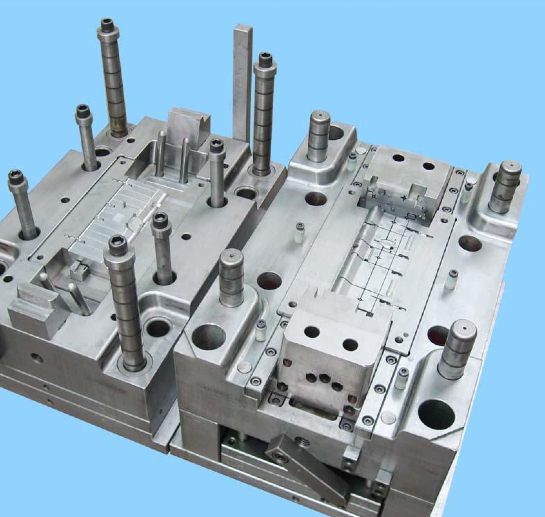

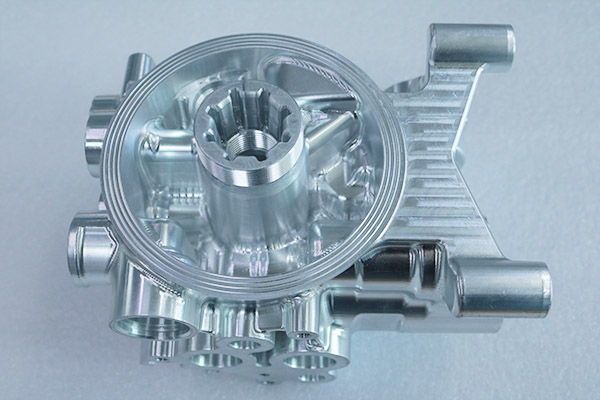

All rapid prototying jobs begin with digital models, but manufacturing hardware can range between CNC machining, 3D printing, and more.

You can make rapid prototypes from any material that’s compatible with the manufacturing hardware that you use. This might or might not include surface finishing treatments.

As its name implies, rapid prototyping puts an emphasis on fast turnarounds. Because when you want to develop and ship a product using rapid prototyping services, faster is always better.